Imagine a space where even the tiniest particle could jeopardize your entire operation. In the pharmaceutical industry, the stakes are high, and maintaining a pristine environment is crucial.

If you’re in charge of a pharma facility, you know that the construction of your clean room isn’t just another task on your list—it’s the very backbone of your success. But what exactly should you be aware of when it comes to clean room construction?

This isn’t just about following a set of rules; it’s about safeguarding your products, reputation, and ultimately, the health of millions. As you read on, you’ll uncover the vital elements that could mean the difference between excellence and error. Ready to ensure your facility is at the forefront of quality and safety? Let’s delve into what every pharma facility should know about clean room construction.

Importance Of Clean Rooms

Clean rooms are crucial for pharmaceutical facilities to ensure product safety and quality. They help maintain controlled environments, reducing contamination risks and ensuring compliance with strict regulations. Proper construction and maintenance of clean rooms are essential for optimal operational efficiency and safeguarding health standards.

Clean rooms are a cornerstone in pharmaceutical facilities. They ensure that the production environment is free from contamination, which is crucial for drug safety and efficacy. Understanding their importance can make a significant difference in maintaining high-quality standards and protecting patient health.What Is A Clean Room?

A clean room is a controlled environment where pollutants like dust, airborne microbes, and aerosol particles are filtered out. The objective is to provide a safe space for manufacturing processes. These rooms are designed to maintain low levels of contamination through strict protocols and specialized equipment.Why Clean Rooms Matter In Pharma

You might wonder why clean rooms are so critical in the pharmaceutical industry. The reason is simple: contamination can compromise drug quality. This could lead to ineffective treatments or harmful side effects, putting patients at risk and damaging a company’s reputation.Ensuring Product Safety

Clean rooms play a vital role in ensuring product safety. They help in minimizing the risk of product contamination during the manufacturing process. This focus on cleanliness directly impacts the effectiveness of the drugs produced, ensuring they are safe for consumer use.Regulatory Compliance

Pharmaceutical companies are subject to stringent regulations. Clean rooms are often a requirement to meet these standards. Failure to comply can result in hefty fines and production shutdowns, which can be costly and damaging to a brand’s reputation.The Role Of Technology In Clean Rooms

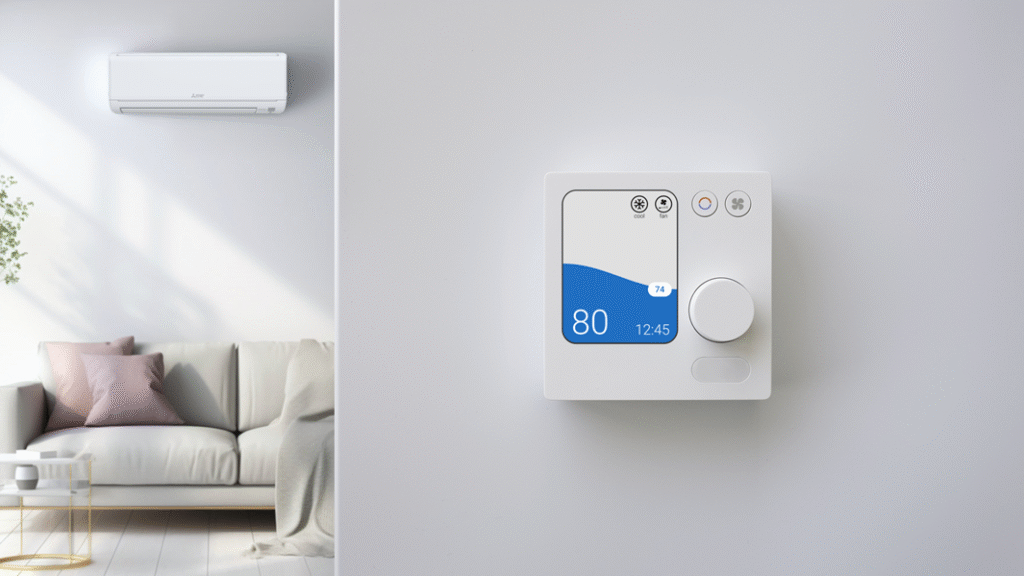

Technology plays a huge role in maintaining the integrity of clean rooms. Advanced HVAC systems, HEPA filters, and real-time monitoring systems are just a few examples. These technologies ensure that the environment remains within specified contamination levels, providing peace of mind and operational efficiency.Practical Tips For Maintaining Clean Rooms

Maintaining a clean room requires vigilance and routine. Regular cleaning, proper gowning procedures, and continuous monitoring are crucial. Remember, even a small oversight can lead to significant contamination, affecting product quality and safety.Personal Experience: A Lesson In Diligence

I once visited a pharma facility where a minor oversight in clean room protocol led to a batch recall. It was a humbling reminder of the importance of diligence in clean room maintenance. This experience underscores the need for strict adherence to protocols to prevent costly mistakes. Clean rooms are not just about meeting regulatory requirements; they are about ensuring the safety and efficacy of pharmaceutical products. Are you confident that your clean room protocols are up to par? If not, it might be time for a thorough review.

Credit: hscnews.usc.edu

Key Design Considerations

Constructing a clean room for a pharmaceutical facility isn’t just about ticking off a checklist. It’s about understanding the intricate details that ensure efficiency and safety. Every choice you make in the design process impacts the final functionality of the clean room. From airflow to materials, each aspect plays a crucial role. Dive into these key design considerations to ensure your clean room stands the test of time and meets all regulatory standards.

Airflow And Ventilation

Imagine walking into a clean room where every breath feels crisp and pure. That’s the power of optimal airflow and ventilation. Proper air circulation prevents contamination and maintains a sterile environment. You should consider the layout of HVAC systems and ensure air filters are of high quality. An efficient airflow design not only safeguards the product but also the personnel within.

Consider using laminar airflow systems. These systems guide air in a uniform manner, reducing turbulence and minimizing the risk of airborne particles settling. Regular maintenance checks on your ventilation system are essential. Have you ever thought about the impact of airflow direction on contamination control?

Material Selection

Choosing the right materials can make or break your clean room. Materials should be easy to clean and resistant to chemicals. Think of surfaces that won’t harbor bacteria or contribute to particle generation. Stainless steel, specialized plastics, and epoxy paints are popular choices for clean room construction.

It’s crucial to select materials that withstand frequent cleaning procedures. Consider the durability of floors and walls, as they will be subjected to constant wear and tear. Have you considered the balance between cost and quality in material selection?

Space Utilization

Effective space utilization maximizes efficiency and workflow. Plan your space to accommodate equipment, personnel movement, and storage. Every square inch counts, especially in facilities where precision is paramount.

Think about vertical space. High shelving can free up floor area and enhance organization. Create designated zones for specific tasks to streamline operations. How can you optimize your clean room layout to boost productivity?

Constructing a clean room is a meticulous process, but with thoughtful design considerations, you can create an environment that excels in performance and safety.

Regulatory Standards

Understanding regulatory standards is crucial for clean room construction in pharma facilities. Compliance ensures safe, controlled environments for sensitive drug manufacturing. Prioritizing these guidelines is essential for maintaining product quality and patient safety.

Constructing a clean room for a pharmaceutical facility is a critical task. Regulatory standards are at the heart of this endeavor. They ensure the environment is safe, sterile, and compliant with industry norms. But navigating these regulations can be daunting. You might wonder, “What standards should I be aware of?” Let’s break it down into two main components: ISO Classification and FDA Guidelines.Iso Classification

ISO classification defines the cleanliness level of a clean room. It’s measured by the number of particles per cubic meter. The lower the ISO class number, the cleaner the room. Imagine walking into a room and knowing that every particle is counted. ISO standards range from ISO Class 1 to ISO Class 9. For pharmaceutical facilities, ISO 5 to ISO 8 are most common. Why is this important for you? A small mistake in particle count can compromise your product’s integrity. Monitoring air quality is crucial. Consider using advanced filtration systems to maintain the desired ISO class. Regular audits and checks can prevent contamination risks and protect your product quality.Fda Guidelines

FDA guidelines focus on safety and efficacy in drug manufacturing. They cover a wide range of areas, including facility design and quality control. You need to ensure your clean room meets these standards. It’s not just about compliance; it’s about building trust with your consumers. Ask yourself, “How can I align my construction with FDA expectations?” Start with documentation. Keep detailed records of your clean room’s operations and maintenance. This is not just a bureaucratic task—it’s a tool for accountability. Regular inspections and staff training are vital. These actions foster a culture of quality and safety. In your clean room journey, the path to compliance may seem overwhelming. But knowing the rules means you can play the game wisely. Stay informed, ask questions, and make informed decisions. What step will you take today to ensure your clean room meets regulatory standards?Construction Challenges

Building a clean room for a pharma facility presents unique challenges. Ensuring airtight seals, controlling airflow, and maintaining strict hygiene standards are crucial. Every detail matters to prevent contamination and ensure compliance with regulations.

Building a clean room for a pharmaceutical facility is no small feat. It requires meticulous planning and execution to ensure the space meets stringent standards. Construction challenges are inevitable, but understanding them can make the journey smoother. Whether you’re dealing with maintaining sterility, managing costs, or meeting tight deadlines, each aspect demands careful consideration and strategic planning.Maintaining Sterility

Ensuring a sterile environment during construction is crucial. You might think, “How can we keep dust out while building?” It’s all about using specialized materials and techniques. Consider using airlocks and HEPA filters even during construction. These can help in minimizing contamination risks. Regular monitoring of air quality also keeps your construction on track.Cost Management

Budgeting is a major hurdle. It’s easy to get lost in unforeseen expenses. You need a clear plan and frequent reviews to stay within your budget. Think about the costs of materials, labor, and equipment. Are there ways to cut costs without compromising quality? Using prefabricated components can sometimes save money and time. Always weigh the pros and cons before making decisions.Time Constraints

Meeting deadlines can be stressful. Time is money, especially in pharma construction. You must prioritize tasks effectively to avoid costly delays. Breaking down the project into smaller, manageable phases can help. Are there parts of the project that can be worked on simultaneously? Perhaps you can start setting up HVAC systems while the flooring is being laid. Efficient scheduling is key to success. So, how can you tackle these challenges effectively? It’s all about preparation, flexibility, and constant communication. Are you ready to face these hurdles head-on and build a clean room that stands the test of time?Advanced Technologies

Constructing clean rooms is vital for pharma facilities. These spaces ensure that sensitive drug manufacturing processes remain uncontaminated. Key elements include air filtration systems, antimicrobial surfaces, and controlled environments, all of which help maintain product safety and quality.

Clean room construction is rapidly evolving with advanced technologies paving the way for more efficient and safer pharmaceutical facilities. These innovations are not just fancy upgrades; they are essential for maintaining the highest standards in cleanliness and operational efficiency. How can these advancements transform your facility and ensure compliance with stringent industry regulations?Smart Monitoring Systems

Imagine having the ability to monitor every aspect of your clean room environment in real-time. Smart monitoring systems make this possible by offering continuous oversight of temperature, humidity, and particle levels. These systems provide instant alerts, allowing you to address issues before they escalate. With data analytics, you gain insights into trends and potential risks. This proactive approach not only enhances safety but also optimizes operational efficiency. Is your facility leveraging the power of smart monitoring to stay ahead of potential disruptions?Innovative Filtration Solutions

Advanced filtration solutions are crucial for maintaining the purity of your clean room environment. High-efficiency particulate air (HEPA) and ultra-low penetration air (ULPA) filters are now more effective than ever. These filters capture even the smallest contaminants, ensuring your facility meets the highest cleanliness standards. The latest innovations include self-cleaning and energy-efficient filters, reducing maintenance needs and operational costs. Additionally, some systems offer modular designs, allowing you to adapt to changing requirements with ease. Are your current filtration systems up to the challenge of evolving industry standards? Incorporating these advanced technologies can significantly enhance the performance of your clean room. As you evaluate your facility’s needs, consider how these innovations could be integrated to not only meet compliance but also exceed it.

Credit: www.mecart-cleanrooms.com

Maintenance And Operation

Clean room construction in pharma facilities demands careful maintenance and operation. Ensuring a sterile environment minimizes contamination risks. Regular checks and proper protocols are essential for optimal performance.

Maintaining and operating a clean room in a pharma facility is no small task. It requires precision, dedication, and an unwavering commitment to standards. Without a robust maintenance and operation plan, even the most advanced clean rooms can fall short of their purpose. So, how do you ensure your clean room runs smoothly and safely?Routine Cleaning Protocols

Routine cleaning is the backbone of clean room maintenance. Regular, thorough cleaning keeps contaminants at bay and ensures a sterile environment. But what does a solid cleaning protocol look like? Consider a detailed checklist that includes daily, weekly, and monthly tasks. Daily tasks might involve wiping down surfaces and mopping floors. Weekly tasks could include changing air filters and inspecting equipment. Monthly tasks might involve deep cleaning of ventilation systems. Does your team follow a similar checklist? If not, it might be time to develop one.Staff Training And Compliance

Your staff is the heart of your clean room operations. Proper training ensures everyone understands their role in maintaining cleanliness. Have you invested enough in training? Regular workshops and refresher courses can keep your team updated on the latest standards. Create engaging sessions that cover everything from donning protective gear to understanding contamination risks. But training is only part of the equation. Compliance is key. How do you ensure your team follows protocols consistently? Consider regular audits and feedback sessions. Recognizing and rewarding compliance can boost morale and encourage adherence to standards. Each of these elements plays a crucial role in maintaining a clean room. It’s not just about ticking boxes but creating a culture of excellence. Are your maintenance and operation protocols up to the task?Future Trends

Clean room construction is evolving rapidly in the pharmaceutical sector. Facilities must stay informed about emerging trends. These trends promise to enhance efficiency, sustainability, and technological integration. Understanding these future directions is crucial for any pharma facility aiming for success.

Sustainable Construction Practices

Sustainability is gaining importance in clean room construction. Eco-friendly materials are becoming more popular. They reduce environmental impact without sacrificing quality. Energy-efficient designs are in demand. They help lower operational costs and reduce carbon footprints. Green certifications are now a priority. Many facilities seek them to showcase their commitment to the environment. Recyclable materials are being used more frequently. They align with global sustainability goals.

Integration Of Ai And Automation

AI is transforming clean room operations. Automated systems enhance precision and reduce human error. They ensure consistent quality and safety. Smart sensors are crucial. They monitor air quality and temperature changes. AI-driven analytics provide valuable insights. They help in predicting maintenance needs and optimizing operations. Robotics are increasingly used for routine tasks. They free up human resources for more complex challenges. Automation is improving efficiency across the board.

Credit: www.mecart-cleanrooms.com

Frequently Asked Questions

What Are The Requirements For A Clean Room In Pharma?

Clean rooms in pharma require controlled air quality, temperature, humidity, and pressure. They must have filtration systems, proper gowning protocols, and regular monitoring. Surfaces should be easy to clean and materials must be non-reactive. Compliance with GMP standards and ISO classifications is essential for maintaining sterility and preventing contamination.

What Are The Gmp Guidelines For Clean Rooms?

GMP guidelines for clean rooms include strict cleanliness standards, controlled environments, and regular monitoring. Implement HEPA filtration systems and maintain temperature, humidity, and pressure. Conduct regular cleaning and validation. Train staff on hygiene and contamination control. Use proper gowning procedures to minimize contamination risks.

Why Clean Rooms Are Important In Pharmaceutical Industry?

Clean rooms ensure contamination control in pharmaceuticals. They maintain sterile environments for drug production, safeguarding product quality and patient safety. Proper cleanliness prevents microbial growth, ensures compliance with regulations, and avoids costly recalls. This critical environment supports the industry’s commitment to delivering safe and effective medications.

What Is Iso 5 Clean Room Specification?

ISO 5 clean room specification limits particles to 100 per cubic meter. It ensures high cleanliness standards. Industries like pharmaceuticals and electronics often use ISO 5 clean rooms. Stringent control of air quality, temperature, and humidity is maintained. Proper filtration systems are crucial for compliance with ISO 5 standards.

Conclusion

Building a clean room in a pharma facility is crucial. It ensures product safety and quality. Proper planning and design are essential. Clean rooms must meet strict standards. Every detail matters, from airflow to materials. Regular maintenance keeps them efficient.

Staff training is also vital. It prevents contamination and ensures smooth operations. Investing in a well-built clean room pays off. It protects both products and patients. Understanding these basics is key. Make informed decisions for your facility. Prioritize safety and compliance.

Your pharma facility’s success depends on it.