Performance-Driven Clean Room Design & Execution

Our reputation is built on delivering compliant, high-performance clean rooms that add measurable value to your operations. For us, results go beyond construction—they’re about regulatory readiness, airflow efficiency, and contamination control that protect your products and processes.

We focus on clean room environments that deliver ROI by reducing downtime, meeting GMP/ISO standards, and optimizing operating efficiency through precise engineering and execution.

- ISO/GMP-compliant room design & planning

- Airflow zoning & contamination control strategy

- HEPA/ULPA filtration system integration

- Modular or hard-wall panel system setup

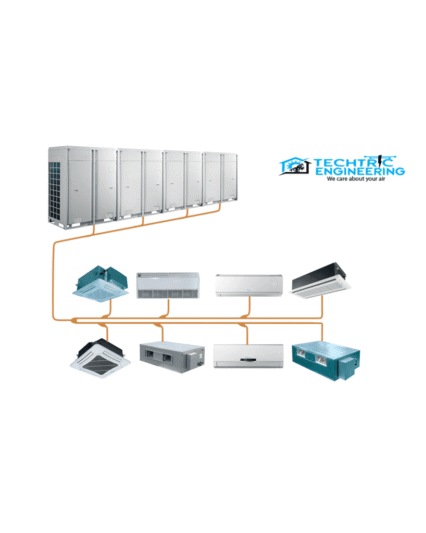

- HVAC with pressure differential & temperature control

- Validation, testing & documentation

- Compliance training and post-installation support

TTiTCNBD

How Our Clean Room Solutions Help Improve Compliance & Operational Efficiency

Combining Clean Room Engineering with Process Optimization

The secret to a truly effective clean room isn’t just about walls and filters—it’s about creating an environment that actively supports your production process, regulatory compliance, and long-term operational goals.

Many providers focus solely on installation, without tailoring airflow zoning, contamination control, or HVAC performance to your facility’s specific needs. These generic builds often fail to meet audit standards, cause production delays, or lead to higher operational costs.

At TTiT China Bangladesh Ltd., we go beyond standard construction. We design and deliver GMP/ISO-compliant clean rooms that are engineered to perform. For example, if your clean room fails to maintain pressure differentials consistently, it may risk microbial contamination or process deviation. We ensure that doesn’t happen—by planning around your workflow, material flow, personnel movement, and critical zones.

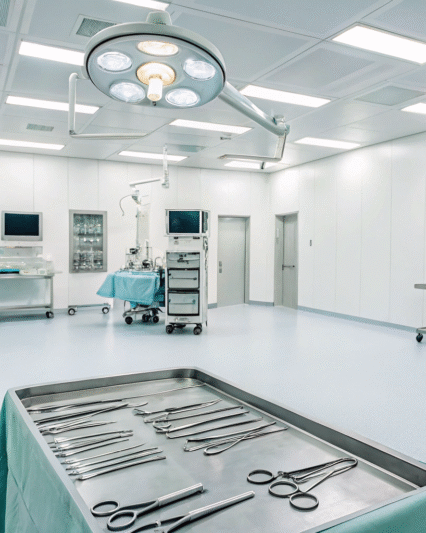

Real Clean Room Engineering Experts

Work with a team of certified clean room specialists who have years of hands-on experience designing and delivering ISO and GMP-compliant environments across pharma, biotech, healthcare, and electronics sectors. We combine deep industry knowledge with precise execution to ensure your clean room meets regulatory standards—without delays or surprises.

what you get

What’s included in our clean room turnkey solutions?

When you partner with TTiT China Bangladesh Ltd., you gain access to a comprehensive suite of clean room services. Our solutions are designed to ensure full compliance, operational efficiency, and long-term performance across every stage of your clean room project.

clean room design

and Filtration

and Compliance Support

clean room design

ISO/GMP-compliant

clean room design

We begin by understanding your process requirements, layout constraints, and regulatory obligations. Our team develops a customized clean room design that aligns with ISO 14644-1 classifications and GMP standards. This includes airflow planning, contamination control zoning, material/personnel flow, and HVAC load assessments.

Modular or Hard-Wall Construction with Precision Finishes

We build your clean room using modular panels or solid wall systems, depending on your industry and classification needs. All surfaces are selected for smoothness, anti-microbial properties, and easy cleanability—ideal for pharmaceutical, biotech, and electronics manufacturing environments.

and Filtration

Advanced HVAC and Filtration Integration (HEPA/ULPA)

We integrate HVAC systems specifically designed for clean room applications. This includes temperature and humidity control, HEPA/ULPA air filtration, air exchange calculations, and pressure control. We ensure proper airflow direction and particle retention to maintain your desired class level.

and Compliance Support

Ongoing Maintenance and Compliance Support

After handover, we offer ongoing maintenance contracts to ensure sustained performance. This includes filter replacements, pressure balancing, routine inspections, and audit prep support. Our goal is to keep your clean room compliant, efficient, and audit-ready 24/7.

Creating Success

What makes our clean room solutions so effective?

Engineering for Process and Compliance

Designing a clean room is more than walls and filters—it’s about matching your process flow with precision zoning, air quality standards, and contamination control systems. We align every technical detail with your operational needs to ensure ISO and GMP readiness from day one.

Experienced Project Execution

How do you know your clean room will pass inspection? Because we’ve done it—again and again. Our engineers and project managers have years of experience delivering validated clean rooms across pharmaceuticals, healthcare, and tech industries—with results that speak for themselves.

Global-Local Collaboration

As a joint initiative between Chinese technical experts and Bangladeshi execution teams, we bring the best of both worlds: advanced engineering knowledge, local responsiveness, and cost-effective project delivery—powered by strong international standards.

The ITEMs QURATED FROM AUTHENTIC SOURCES

Clean Room that meets your Industrial Needs

FAQ

FAQs about Clean Room Solutions

Looking to learn more about clean room solutions for your business? Browse our FAQs:

We serve a wide range of sectors including pharmaceuticals, biotechnology, electronics, healthcare, food processing, and research laboratories.

We design and construct clean rooms according to international standards such as ISO 14644, GMP, WHO, and FDA guidelines—based on your regulatory needs.

Yes. We conduct full validation and testing, including particle count, airflow visualization, and pressure differential tests, and provide complete documentation for audit compliance.

Project timelines vary depending on size and complexity. On average, a clean room project takes 6–12 weeks from design to final validation.