Are you facing the daunting task of getting your clean room ready for regulatory approval? You’re not alone.

Navigating the maze of compliance and standards can feel overwhelming, but with the right guidance, you can streamline this process. Imagine the relief of knowing that your clean room not only meets, but exceeds, regulatory expectations. This guide will walk you through the crucial steps of validation, demystifying the process so you can focus on what really matters—delivering quality products.

Dive in to discover the key strategies that will empower you to achieve seamless regulatory approval. Your clean room’s success starts here.

Clean Room Validation Basics

Clean room validation is essential in industries like pharmaceuticals and biotechnology. It ensures that the environment is free from contaminants. This process is crucial for maintaining product quality and safety. Understanding the basics of clean room validation helps meet regulatory requirements.

Purpose Of Validation

The primary aim of validation is to confirm the room’s cleanliness. It checks the room’s ability to control contamination. This ensures that products are safe for use. Validation protects both the product and the consumer.

It also verifies the room’s compliance with industry standards. This step ensures that the room operates as intended. Regular validation helps detect potential issues early.

Regulatory Standards

Regulatory standards guide the validation process. They provide a framework for maintaining room cleanliness. Agencies like the FDA and EMA set these standards. They ensure uniformity and safety across industries.

Standards cover aspects like air quality, surfaces, and personnel practices. Meeting these standards is crucial for regulatory approval. Compliance demonstrates a commitment to quality and safety.

Design Considerations

Designing a clean room is essential for regulatory approval. The design impacts functionality, efficiency, and compliance. Careful planning ensures the space meets strict standards. Consider key factors like layout, airflow, and material selection. Each element plays a vital role in achieving a clean and controlled environment.

Layout And Airflow

The layout of a clean room should optimize workflow. Ensure there is a smooth flow of operations. Equipment and stations should be positioned strategically. This minimizes contamination risks. Proper airflow is crucial for maintaining cleanliness. Use high-efficiency particulate air (HEPA) filters. These filters remove contaminants effectively. Design airflow to create positive pressure. This prevents unclean air from entering the room. Maintain consistent air changes per hour (ACH). This ensures a steady supply of clean air.

Material Selection

Choose materials that are easy to clean. This reduces contamination risks. Surfaces should be smooth and non-porous. This prevents bacteria growth. Use materials resistant to chemicals and disinfectants. This ensures durability and long-term performance. Flooring should be seamless and non-slip. Walls and ceilings must be sealed properly. This helps maintain a controlled environment. Select furniture and fixtures designed for clean rooms. Their design should minimize particle generation.

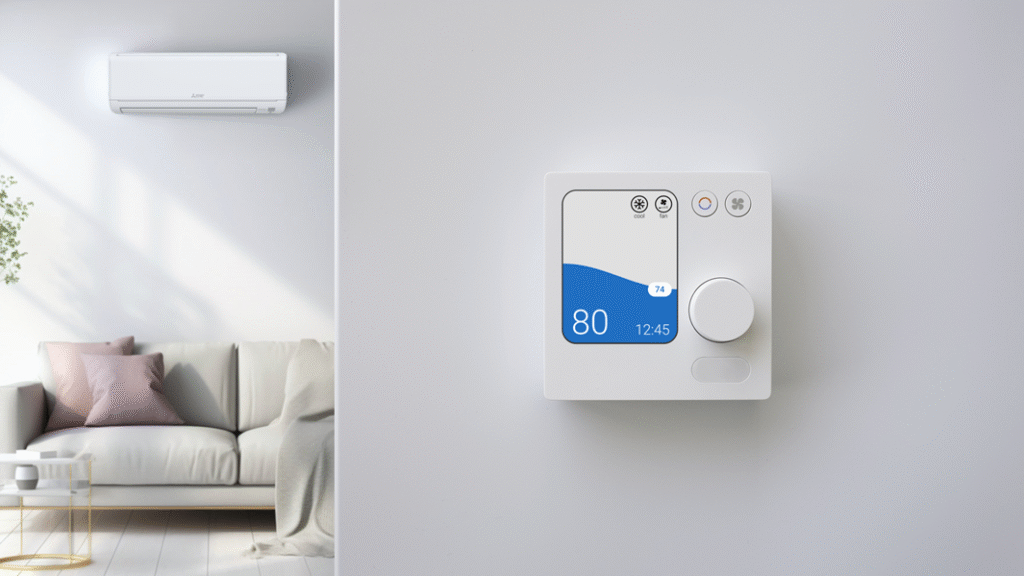

Environmental Controls

Creating a clean room that meets regulatory approval requires a keen focus on environmental controls. These controls are vital to maintaining the integrity and safety of your clean room. By focusing on specific aspects like temperature, humidity, and air filtration, you can ensure your clean room is up to par with industry standards. Let’s dive into these critical components and explore how they contribute to a successful clean room validation.

Temperature And Humidity

Temperature and humidity are not just numbers on a screen; they dictate the entire environment of your clean room. Maintaining the right temperature can prevent equipment malfunctions and ensure worker comfort. Meanwhile, controlling humidity helps in reducing particle generation and static electricity, which can affect sensitive processes.

Consider using automated systems to monitor these parameters. This real-time monitoring ensures that any deviations are immediately flagged. Have you ever walked into a room and felt the air was just right? That’s the level of precision you should aim for in your clean room.

Air Filtration Systems

The air filtration system is the backbone of any clean room. It keeps out dust, microbes, and other contaminants that could compromise your processes. High-Efficiency Particulate Air (HEPA) filters are often the go-to choice, capturing particles as small as 0.3 microns.

Regular maintenance and testing of these systems are crucial. Imagine a scenario where a clogged filter goes unnoticed; it could lead to a cascade of issues affecting product quality and regulatory compliance. Do you have a schedule for filter replacement and system checks? If not, it’s time to implement one.

Involving your team in these processes can be beneficial. They can offer insights into how the systems work in practice and identify areas for improvement. What changes can you make today to ensure your clean room is always up to standard?

Credit: insights.citeline.com

Operational Protocols

Operational protocols are the backbone of maintaining a clean room that meets regulatory standards. These protocols ensure that every aspect of the clean room functions optimally, safeguarding product quality and compliance. A key part of these protocols involves thorough personnel training and meticulous cleaning procedures. Let’s delve into these crucial elements.

Personnel Training

Your team is the first line of defense in maintaining a clean room. Proper training equips them with the skills to minimize contamination risks. Have you considered how training impacts regulatory approval?

Focus on hands-on training sessions. These sessions offer practical experience in managing clean room conditions. Trainers should emphasize the importance of hygiene and correct equipment usage.

Regular refresher courses are vital. They ensure your team is up-to-date with the latest protocols and standards. This continuous learning fosters a culture of accountability and precision.

Cleaning Procedures

Cleaning procedures are not just about keeping the room spotless. They’re about maintaining an environment free of contaminants. How rigorous are your current cleaning protocols?

Implement a checklist system for daily cleaning tasks. This system ensures no step is overlooked. Assign responsibilities clearly among personnel for each task.

Use approved cleaning agents. These agents should be effective yet safe for sensitive equipment. Also, schedule routine deep-cleaning sessions to tackle areas prone to buildup.

Document every cleaning activity. This documentation is crucial for audits and demonstrates your commitment to maintaining high standards. An organized record can be your best ally in achieving regulatory approval.

Validation Testing Procedures

Validating a clean room for regulatory approval is a crucial step in ensuring that your facility meets stringent quality standards. Validation testing procedures play a pivotal role in this process. They help confirm that your clean room operates within the required specifications to maintain a contaminant-free environment. Understanding these procedures not only helps you comply with regulations but also ensures the safety and efficacy of your operations. Let’s dive into two key aspects of validation testing: particle counting and microbiological sampling.

Particle Counting

Particle counting is an essential part of clean room validation. This process measures the number and size of particles in the air. Specialized equipment, like particle counters, are used to capture and analyze these particles. You should conduct particle counting at various points in your clean room, such as near workstations and air filters.

Regular particle counting helps identify potential contamination sources. If particle levels exceed acceptable limits, it might indicate a need for improved cleaning protocols or equipment maintenance. Have you considered how often you conduct these tests? Increasing the frequency might uncover trends that sporadic testing misses.

Microbiological Sampling

Microbiological sampling involves collecting and analyzing samples to detect microorganisms. Swabs, contact plates, or air samplers can be used for this purpose. This testing is vital because even invisible microorganisms can compromise your clean room environment.

Consistent microbiological sampling can help you track contamination sources and trends. Are you using a variety of sampling methods to get a comprehensive view? Combining different techniques can provide more robust data. You might find unexpected hotspots of microbial activity that require attention.

Both particle counting and microbiological sampling are integral to the validation testing procedures of a clean room. They ensure that your environment remains within the required standards. By regularly performing these tests, you not only comply with regulatory standards but also safeguard the quality of your operations. What steps will you take today to enhance your clean room validation process?

Credit: in.linkedin.com

Documenting Validation

Validating a clean room for regulatory approval involves thorough documentation of procedures and environmental controls. Ensure protocols meet standards by recording airflow, particle counts, and sanitation processes. Proper documentation helps in compliance and maintaining the integrity of the clean room environment.

Documenting validation is a crucial step in the process of getting regulatory approval for a clean room. It’s where all your meticulous work comes to life on paper. Proper documentation not only ensures compliance but also provides a clear trail of evidence showing that your clean room meets all necessary standards. Let’s break down this process further with the focus on record keeping and compliance reporting.Record Keeping

Accurate and comprehensive record keeping is the backbone of clean room validation. Think of it as your clean room’s detailed diary that captures every significant event. These records include everything from standard operating procedures (SOPs) to equipment maintenance logs. Imagine a time when a minor deviation occurred during your clean room operations. Without proper records, it might have been challenging to pinpoint the cause. However, with detailed logs, you can easily trace the issue and make necessary corrections. Maintaining detailed records also prepares you for audits. When auditors come knocking, having all documents in place saves time and shows that you run a tight ship. They’re looking for consistency and reliability, which your records should clearly demonstrate.Compliance Reporting

Compliance reporting is your opportunity to showcase how your clean room stands up to regulatory scrutiny. These reports should clearly outline how your processes align with industry standards. They’re your evidence that you’re meeting all necessary regulations. Picture a scenario where your clean room is up for inspection. A comprehensive compliance report can make the difference between a smooth process and a stressful one. It provides inspectors with a clear overview of your operations and adherence to guidelines. Your compliance reports should be detailed yet straightforward. Use clear language and structured formats to present your data. Tables and charts can make complex data more digestible for regulators. Remember, the goal is to convey your dedication to quality and safety without overwhelming the reader. Is your documentation robust enough to withstand scrutiny? Ensuring clarity and thoroughness in record keeping and compliance reporting may make all the difference in achieving regulatory approval.Addressing Non-compliance

Validating a clean room ensures compliance with regulatory standards. Regular inspections and testing are essential. Addressing non-compliance involves immediate corrective actions and thorough documentation.

Addressing non-compliance in clean room validation is crucial. It ensures the room meets regulatory standards. Ignoring issues can lead to serious consequences. Addressing these challenges promptly can save time and resources. This section explores how to identify and correct non-compliance.Identifying Issues

Spotting non-compliance requires a keen eye. Regular inspections help. Check for visible dirt or dust. Monitor temperature and humidity levels. Look for any equipment malfunctions. Use particle counters to check air quality. Ensure all personnel follow protocols. Review records for any missed checks. Identifying these issues early can prevent bigger problems.Corrective Actions

Correcting non-compliance is vital. Start with cleaning the affected areas. Repair or replace faulty equipment. Retrain staff on proper procedures. Adjust environmental controls as needed. Update documentation to reflect changes. Conduct a follow-up inspection. Ensure all corrective actions are effective. Document these actions thoroughly. This ensures future compliance and builds trust with regulators.Final Approval Process

In the clean room validation journey, the final approval process is a pivotal step that determines if your clean room meets regulatory standards. This phase is crucial because it’s the bridge between your hard work and the official green light from regulatory bodies. Getting it right can be the difference between moving forward with production or facing costly delays.

Audit Preparation

Preparation is key to passing the audit with flying colors. Begin by ensuring all documentation is up-to-date and easily accessible. Checklists can be your best friend here—make one for every aspect of the clean room, from equipment maintenance logs to staff training records.

Consider a dry run to familiarize your team with the audit process. This can help identify any potential issues before the actual audit. Imagine the confidence you’ll feel when you know every detail is covered and your team is ready.

Regulatory Review

During the regulatory review, officials will scrutinize your clean room’s adherence to standards. They’ll look at air quality, contamination control protocols, and more. Make sure your environmental monitoring systems are in top-notch condition.

Expect questions about your processes and procedures. Be ready to provide detailed explanations and evidence to back up your compliance claims. Think about this: what would you need to see to be convinced your clean room is up to par?

Remember, the final approval process is not just a bureaucratic hurdle. It’s an opportunity to showcase your commitment to quality and safety. How prepared are you for this critical step? Whether it’s your first or fiftieth clean room, each approval process holds its unique challenges and triumphs. Embrace the journey with confidence, knowing every step brings you closer to operational success.

Credit: en.tokyofuturestyle.com

Frequently Asked Questions

How Do You Validate A Cleanroom?

Validate a cleanroom by conducting particle count tests, airflow measurements, and surface sampling. Ensure equipment calibration and perform regular monitoring. Check compliance with ISO standards and document results. Train personnel on procedures and maintain strict protocols for contamination control. Regular audits help ensure ongoing cleanroom validation.

What Are The Fda Requirements For A Clean Room?

The FDA requires clean rooms to maintain controlled environments. They must adhere to ISO classifications, ensuring specific air cleanliness levels. Proper filtration, pressure controls, and monitoring systems are essential. Regular cleaning, validation, and documentation are necessary for compliance. Staff must follow strict protocols for hygiene and attire to prevent contamination.

What Is The Iso Standard For Clean Room Validation?

ISO 14644 is the standard for cleanroom validation. It defines classifications, testing methods, and operational guidelines. Cleanrooms must meet specified air cleanliness levels. Regular monitoring ensures compliance with the standard. ISO 14644 helps maintain contamination control in controlled environments.

What Is Requalification Of Clean Room?

Requalification of a clean room involves periodic testing to ensure compliance with specified environmental standards. It verifies performance efficiency, air quality, and contamination control measures. This process includes airflow analysis, particle counts, and filter checks, ensuring the clean room remains suitable for its intended use.

Conclusion

Validating a clean room is crucial for regulatory approval. Start with precise planning. Focus on air quality and contamination control. Regular checks ensure compliance. Train staff on clean room protocols. Keep documentation organized and accessible. Use approved testing methods. Address any issues promptly to maintain standards.

Building a clean room is just the beginning. Ongoing validation protects your investment. It ensures safety and quality. Follow guidelines closely. Aim for excellence. Regulatory approval is achievable with proper validation. Your clean room should meet all requirements. Stay committed to maintaining high standards.