Imagine stepping into your clean room, confident that every detail is meticulously managed, only to discover that a few overlooked mistakes are compromising your efforts. It’s a frustrating scenario that many face, but it doesn’t have to be yours.

You’re about to uncover the top 5 clean room mistakes that could be silently sabotaging your work. More importantly, you’ll learn how to effortlessly avoid them, ensuring your clean room operates at peak efficiency. Whether you’re managing a clean room for pharmaceuticals, electronics, or any other sensitive production, these insights are crucial.

Stay with us, as the secrets to a flawless clean room await you, ready to transform your operations and boost your success.

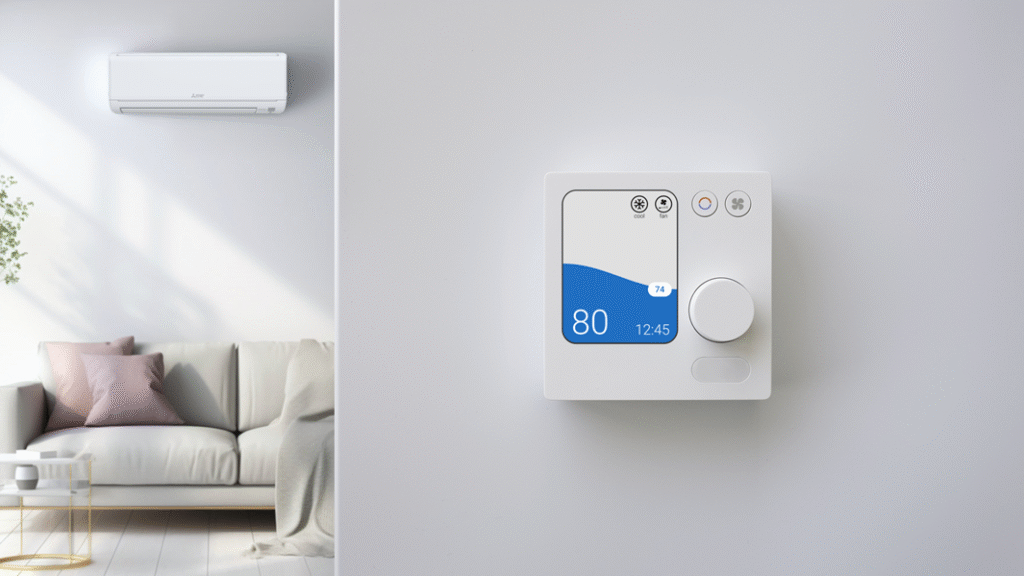

Credit: www.realhomes.com

Common Clean Room Mistakes

Clean rooms need precision and care. Mistakes can lead to contamination. Knowing these mistakes helps maintain a safe environment. Let’s explore common errors and learn how to avoid them.

Neglecting Proper Gowning Procedures

Gowning protects clean rooms from contamination. Many skip steps or rush. This increases risks. Each step in gowning must be followed carefully. Ensure everyone knows the correct procedure.

Inadequate Air Filtration Systems

Clean rooms need high-quality air filters. Faulty systems let particles in. Regular checks and updates are crucial. Ensure filters meet clean room standards. This keeps the environment pure.

Poor Clean Room Maintenance

Regular cleaning keeps rooms contaminant-free. Many forget scheduled maintenance. Dirt and particles can accumulate quickly. Create a strict cleaning schedule. Stick to it without fail.

Lack Of Employee Training

Proper training ensures everyone follows protocols. Some employees might not know them. This can lead to mistakes. Regular training sessions are important. Keep everyone updated on procedures.

Improper Handling Of Materials

Materials need careful handling in clean rooms. Mishandling introduces contaminants. Follow guidelines for each material. Use the right tools and techniques. This ensures safety and cleanliness.

Avoiding Gowning Errors

Clean room environments demand strict adherence to protocols. Gowning errors can jeopardize cleanliness. Avoiding mistakes in gowning is crucial for maintaining a sterile environment. Proper gowning prevents contamination and safeguards the integrity of the clean room.

Importance Of Correct Gowning

Correct gowning keeps contaminants out. It protects the clean room environment. Mistakes in gowning can introduce particles. These particles can affect product quality. Proper procedures ensure safety and cleanliness.

Step-by-step Gowning Guide

Follow a structured gowning process. Start with clean hands. Use soap and water. Dry hands thoroughly. Next, put on shoe covers. Ensure they fit snugly. Wear a hair cover. Tuck all hair inside. Put on a face mask. Cover your nose and mouth. Don the gown carefully. Fasten all ties and snaps. Finally, wear gloves. Ensure they cover your wrists. Check for any gaps or openings.

Review your gowning in the mirror. Ensure everything is secure. Practice these steps regularly. They help maintain the sterile environment. Proper gowning is essential in clean rooms. Avoid mistakes to protect products and processes.

Enhancing Air Filtration

Avoiding common clean room mistakes enhances air filtration efficiency. Poor maintenance and wrong filter choices often compromise air quality. Proper training and regular equipment checks ensure optimal filtration performance.

Enhancing air filtration in a clean room is crucial to maintaining its integrity. A single misstep in filtration can lead to contamination and costly setbacks. With the right strategies, you can ensure your clean room operates smoothly and efficiently.Selecting The Right Filtration System

Choosing the correct filtration system is a fundamental step. Not all filters are created equal. Factors like particle size, airflow, and room size should guide your decision. Think about your specific needs. If your clean room handles sensitive electronics, you may need HEPA filters, which capture 99.97% of particles. On the other hand, for pharmaceutical environments, ULPA filters might be necessary due to their higher filtration efficiency. Consider consulting with filtration experts. Their insights can help you avoid common pitfalls and select a system tailored to your requirements.Regular Filter Maintenance

Once you’ve chosen your filtration system, maintaining it is key. Even the best filters can fail without regular upkeep. Clogged or dirty filters can reduce efficiency and compromise your clean room. Set a maintenance schedule and stick to it. Regular checks can prevent unexpected breakdowns. For instance, inspecting filters monthly can catch issues early. Involve your team in maintenance routines. Educate them on what to look for, like unusual noise or reduced airflow. This collective vigilance ensures your clean room remains uncontaminated and operational. Are you giving enough attention to your clean room’s filtration needs? Neglecting them can lead to significant risks. Prioritize these steps, and your clean room will thank you with optimal performance.Effective Clean Room Maintenance

Effective clean room maintenance is crucial for ensuring product quality. Proper upkeep prevents contamination and safeguards sensitive operations. Maintaining a clean room involves more than just wiping surfaces. It’s about establishing stringent routines and using correct materials. Let’s explore key aspects to ensure optimal clean room conditions.

Routine Cleaning Schedules

Maintaining a consistent cleaning schedule is vital. Regular cleaning reduces potential contamination risks. Daily, weekly, and monthly tasks should be defined clearly. Assign specific duties to trained personnel for efficiency. Each schedule must cater to the room’s unique needs.

Documentation is essential. Record every cleaning session. Track which areas were cleaned and by whom. This helps in accountability and ensures no tasks are missed. Regular audits of cleaning procedures can identify improvements. This keeps maintenance practices updated.

Using Suitable Cleaning Agents

Choosing the right cleaning agents is crucial. Not all products are suitable for clean rooms. Some chemicals might leave residues or harm surfaces. Use agents specifically designed for sensitive environments. These protect equipment and surfaces while ensuring thorough cleaning.

Understanding the materials in the clean room helps in selecting agents. Different surfaces require different cleaning solutions. Always test new cleaning agents on small areas first. Ensure they do not damage or react negatively with surfaces. Proper training on using these agents is also important.

Training For Clean Room Staff

Clean room staff often face common mistakes that can compromise safety and efficiency. Improper gowning, inadequate cleaning procedures, contamination risks, poor documentation, and lack of training are key errors. Avoiding these requires thorough training, regular audits, and updated protocols to maintain a sterile environment.

Training for clean room staff is crucial for maintaining the integrity and efficiency of controlled environments. Mistakes can lead to contamination, costing time and resources. Proper training ensures that your team knows how to minimize risks and maintain high standards. But how can you make sure your staff is adequately trained and constantly improving?Comprehensive Training Programs

Developing comprehensive training programs is essential. Your program should cover everything from the basics of contamination control to advanced techniques specific to your industry. Consider including hands-on workshops, where staff can practice procedures in a controlled setting. Include a variety of learning materials such as videos, manuals, and online courses. This caters to different learning styles and reinforces key concepts. Also, update the training materials regularly to keep up with new technologies and methods. Have you ever taken part in a training session that included real-life scenarios? This approach not only boosts engagement but also prepares staff for potential challenges they might face.Regular Performance Assessments

Regular performance assessments ensure that your staff is applying what they’ve learned effectively. Schedule these assessments at consistent intervals to track progress and identify areas for improvement. Use a mix of practical tests and quizzes to evaluate both theoretical knowledge and practical skills. This dual approach gives you a comprehensive view of your team’s abilities. Provide feedback promptly and constructively. Discuss the results with your staff, highlighting strengths and addressing weaknesses. Encourage them to ask questions and seek clarification on any doubts. How often do you assess your staff’s performance? Frequent assessments not only enhance skills but also boost confidence in handling clean room environments. Incorporating these strategies into your training program can significantly reduce the risk of mistakes in clean rooms. Empower your staff with the knowledge and skills they need to excel in their roles.

Credit: www.facebook.com

Safe Material Handling

Safe material handling is crucial in maintaining clean room standards. Mistakes can lead to contamination and costly setbacks. Understanding the proper techniques for storage and handling is key. This ensures a clean and efficient environment. Here, we explore common errors and ways to avoid them. Focus on safe practices to minimize risks.

Proper Storage Techniques

Proper storage techniques reduce the chance of contamination. Always use designated storage areas for materials. Keep items off the floor and away from walls. Use shelving that is easy to clean. Label all storage containers clearly. This helps in quick identification and reduces handling time. Ensure temperature and humidity controls are set correctly. This preserves material integrity.

Handling Procedures To Minimize Contamination

Handling procedures are vital in minimizing contamination risks. Wear appropriate personal protective equipment (PPE) at all times. Gloves, masks, and gowns are essential. Handle materials with care to avoid spills. Use clean tools and equipment for each task. Regularly sanitize tools to maintain cleanliness. Train staff on proper handling techniques. This minimizes errors and contamination risks.

Credit: www.trualta.com

Frequently Asked Questions

What Are Common Clean Room Mistakes?

Common mistakes include poor airflow management, inadequate cleaning protocols, and incorrect material handling. These errors can compromise contamination control. Regular training and adherence to protocols can help prevent these issues and maintain the clean room’s integrity.

How Can Poor Airflow Affect Clean Rooms?

Poor airflow can lead to contamination buildup and uneven air distribution. This affects product quality and safety. Ensuring proper ventilation and regular maintenance can mitigate these risks, maintaining optimal clean room conditions.

Why Is Material Handling Crucial In Clean Rooms?

Correct material handling prevents contamination and ensures product quality. Mishandling can introduce pollutants, jeopardizing sterile environments. Implementing strict handling procedures and training staff regularly can minimize risks and maintain cleanliness standards.

What Cleaning Protocols Should Be Followed?

Effective cleaning protocols include regular disinfection and use of approved cleaning agents. Proper techniques and schedules ensure contamination control. Training staff and auditing processes can enhance compliance and maintain clean room efficacy.

Conclusion

Avoiding clean room mistakes ensures safety and efficiency. Simple steps make a big difference. Regular training keeps staff informed. Proper equipment maintenance is crucial. Monitor environmental controls closely. Address contamination sources immediately. Consistency is key. Following these tips reduces risks.

Clean rooms stay effective and safe. Remember, small actions lead to big results. Keep the environment controlled and clean. Success in clean room management is achievable. Stay proactive and attentive. Your efforts ensure a safe workspace.